Pressix CC 41 - Channel System

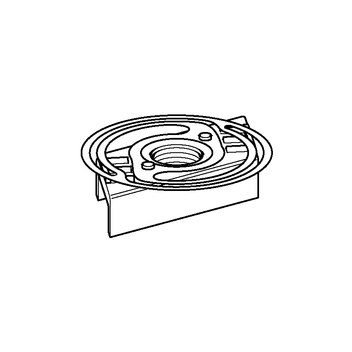

Speed Nut NT CC 41

Application

In particular useful when installing in vertical channels or in places of difficult access.

Further advantages:

- For all Sikla Channels MS 41, independent of the height of the channel.

- No getting stuck on bolt heads when sliding in the channel.

- No appearance of settlement after tightening.

Scope of delivery

Channel Nut and Spring are tightely connected.

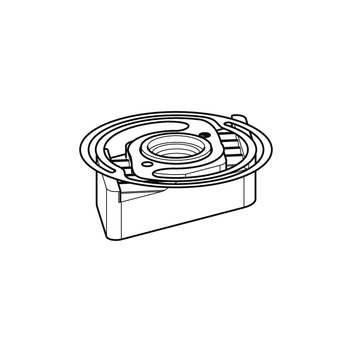

Installation

After inserting the Speed Nut into the channel opening, it is - by exerting slight pressure on it - turned to the right as far as it will go; deinstallation may be effected by following the instructions in reverse order.

Installation and deinstallation do not require tools and may be repeated several times.

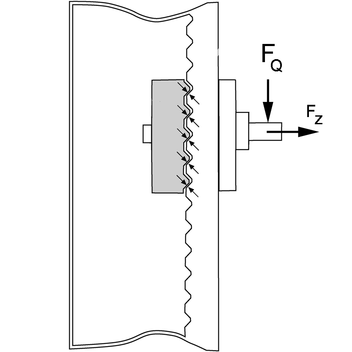

Technical Data

| M6 | M8 | M10 | M12 | M16 | |

| Tightening torque 8.8 1) [Nm] | 10 | 25 | 40 | 80 | 80 |

| 1) | Using lower steel classes, the value are to be reduced accordingly. |

| Channel thickness [mm] | M6 FZ ≤ [kN] | M8 2) FZ ≤ [kN] | M10 2) FZ ≤ [kN] | M12 FZ ≤ [kN] | M16 FZ ≤ [kN] | M6 FQ ≤ [kN] | M8 FQ ≤ [kN] | M10 2) FQ ≤ [kN] | M12 FQ ≤ [kN] | M16 FQ ≤ [kN] | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.5 | 3.0 | 3.0 | 3.0 | 7.5 | 7.5 | 0.7 | 1.8 | 2.9 | 7.5 | 6 | |

| 2.0 | 3.2 | 5.8 | 5.8 | 10 | 10 | 0.9 | 2.1 | 3.4 | 9 | 6 | |

| 2.5 | 3.2 | 5.8 | 5.8 | 11 | 11 | 1.0 | 2.6 | 4.1 | 9 | 6 | |

| 3.0 | 3.2 | 5.8 | 5.8 | 13 | 13 | 1.1 | 2.8 | 4.4 | 9 | 6 |

Note: The permissible load capacities of the channels are to be respected.

| Material: | |

| Nut: | Steel class 5.6, electro-galvanised |

| Spring washer: | Sheet metal spring steel, rustproof |

Approvals / Conformity

| This product has been awarded the RAL quality mark "pipe supports" and is subject to continuous external monitoring according to RAL GZ-655. 2) Tested load values 'connection design' according to certificate 2010-07/2010-09. |